APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contacter maintenant

Because of the all-spherical of the tool function, production unit customized rubber curler groover should make nearly all of the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, at once groove, horizontal groove and exceptional formations in the appended drawing.1. factory customized rubber roller groover has our personal developed user-pleasant cnc operating system.2.

Contacter maintenant

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contacter maintenant

Features:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistance Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers Shipping:

Contacter maintenant

Product Description:Specially used for stability verification of massive and medium-sized motor rotors, blowers, pump impellers, dryers, rollers and different rotating workpieces.The device adopts ring belt power or gear field familiar joint transmission, and frequency conversion motor drive to ensure the balanced nice and precision of the workpiece.The gadget has the characteristics of huge pace range, huge driving energy and high working performance. Model NumberPHQ-3000HPHW-3000H2460-10000HTransmissionBelt DriveUniversal JointUniversal JointWorkpiece weight range (kg)3000300010000Workp

Contacter maintenant

PSM-1680-CNC Rubber Roller Groover / Grooving / Grinder / Grinding MachinesDue to the all-round of the system function, it can make almost all the profile of rollers.

Contacter maintenant

Product description1. The PCM-8040 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacter maintenant

Rubber strainerRubber strainer is the usage of screw push, conveying the function of the glue or recycled gum impurities within the removal of the machinery.it particularly consists of screw, barrel, glue head and transmission device.the filter head is geared up with orifice plate and clear out net, the orifice plate is used to aid the rubber strainer internet and is the discharging port, its aperture is four~8mm, and it is the conical hole which expands alongside the drift path of the rubber cloth.the duration-diameter ratio of the screw in the filter out gadget is set 5.Selection of Rubber F

Contacter maintenant

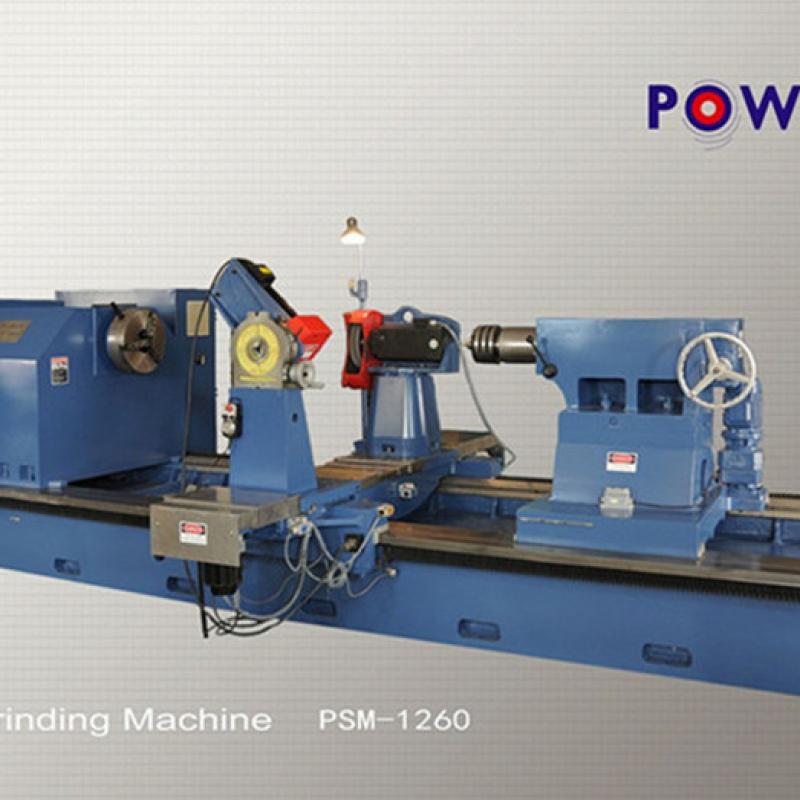

PSM series grinding machine for rubber roller processing is particularly designed and artificial to replace the past roller processing approach with the useful resource of the usage of metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past approach to manufacture roller, which the high-excellent of roller is difficult to acquire the requirement of the present standard. The essential motive lies withinside the form of lathe.

Contacter maintenant

Because of the all-spherical of the device feature, manufacturing unit custom designed rubber roller groover could make nearly all of the profile of rollers. for instance, parabolic crowning and concave, cosine crowning and concave, round, cone, coarse pitch, herringbone, diamond, without delay groove, horizontal groove and exclusive formations within the appended drawing.1.

Contacter maintenant

Psm collection rubber roller grinding device is in particular designed and synthetic to update the beyond roller processing approach thru using manner of metallic production device. installation grinding head at the engine lathe is the past technique to manufacture roller, which the super of curler is hard to gain the requirement of the winning giant. the primary cause lies inside the shape of lathe. ultimately, it isn't the grinding device; the moving regions of the big and medium carriage table are massive than that of grinding tool.

Contacter maintenant

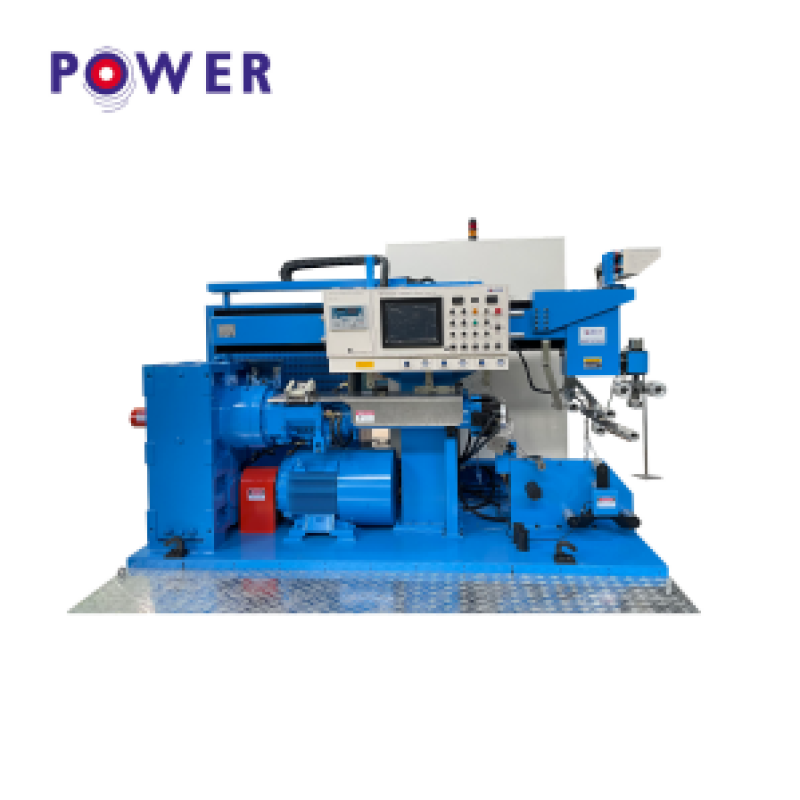

Banbury Rubber mixer machineThe scope application of internal mixer is very wide, such as rubber, synthetic rubber, resin, asphalt, cellulose,P.V.C.E.V.A. raw materials such as P.E, can in the shortest time to complete mixing. The Rubber banbury internal mixer machine body structure is strong and durable. The powder stop equipment can effectively prevent the leakage of raw materials and compound agents through special design. It has long service life, simple operation, good effect and easy maintenance, and it is also very convenient to replace the worn parts.

Contacter maintenant

With the mindset of being expert and sincere, strength agency produces super rubber rollers intently following sci-tech requirement of the instances. numerous operating processes had been introduced to make certain maximum reliable high-quality.With the guideline of excellent first, clients the best, electricity enterprise offers to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of latest base gum and corollary offerings for system manufacturers.Packaging & ShippingPackaging detail: 1.

Contacter maintenant

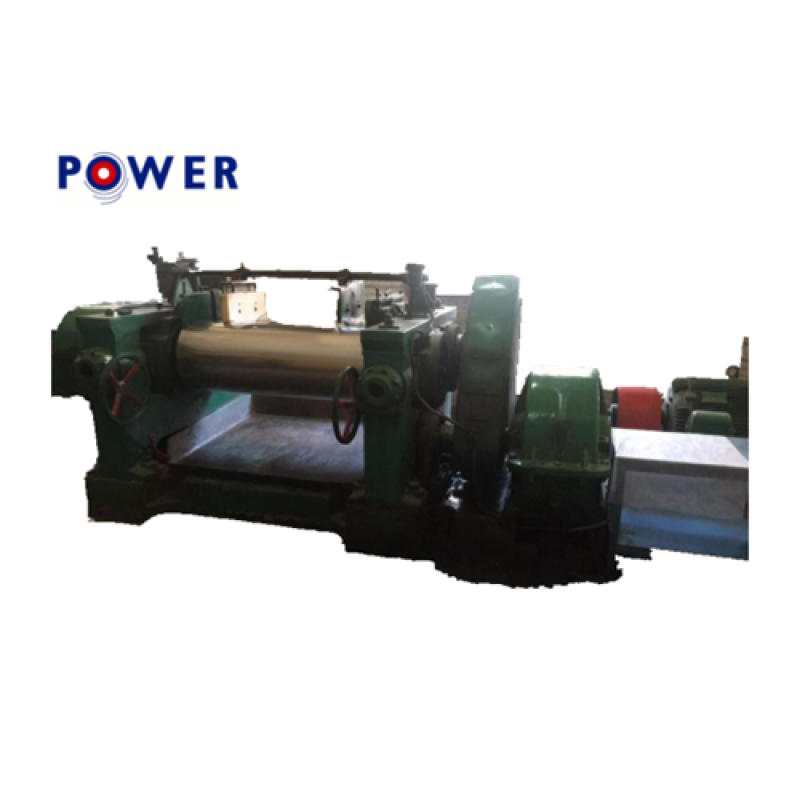

Used Open Rubber Mixing Mill 18" Two Roll / Second-hand Open Rubber Mixing Machine / Used Open Rubber Mixer Mill / Used Open Rubber Mixing MillUsed for rubber mixing and feeding for the next proocess. Second hand used machine with good condition.Product description18" Second-hand Used Rubber Open Mixing MillAbout usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacter maintenant

Function:1. can be used for water throwing and dry throwing;2. rubber belt sprucing and roll middle dehairing belt;3.There are more than one sorts, duration and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contacter maintenant

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weekOur Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Renew service provided.Product use:Shipping photos:

Contacter maintenant

Functions:1 ozone resistance ,weather growing old resistance ,chemical resistance2 warmth growing older resistance ,low temperature overall performance ,oil resistance ,uv resistancePrograms:· car sectors:which include hoses, tubings, excessive temperature timing belts· business sectors :along with seals, lingings, printing rollersShipping:

Contacter maintenant

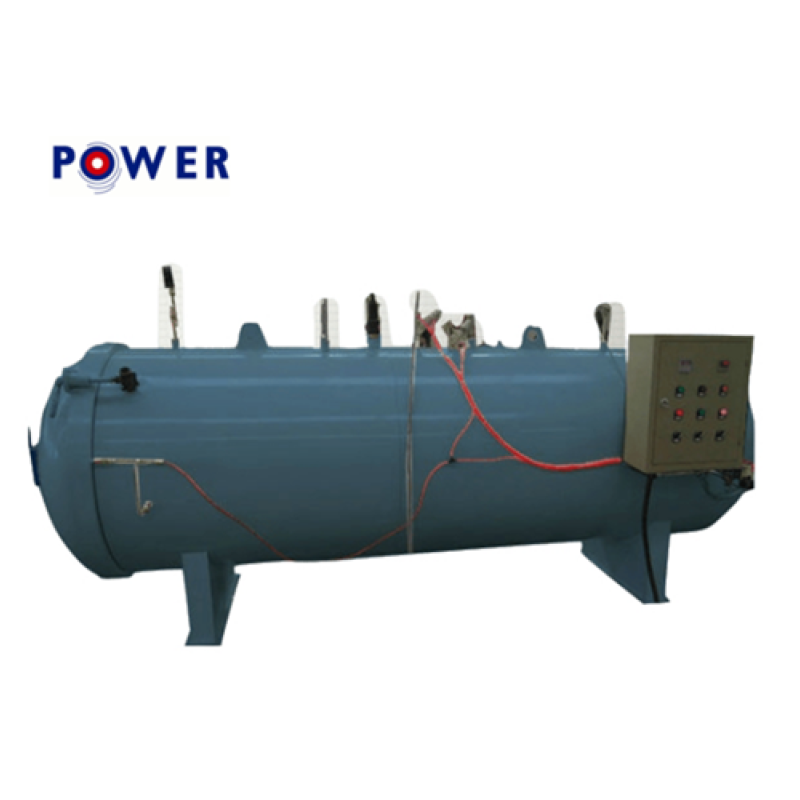

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contacter maintenant

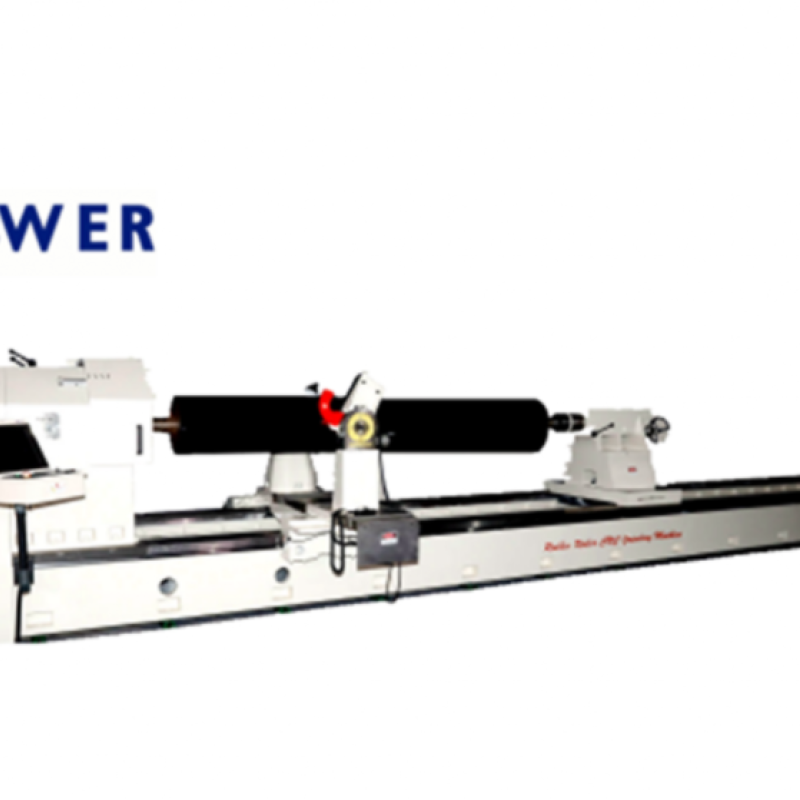

Product Description:Mainly used for balance verification of large and medium-sized motor rotors, blowers, pump impellers, dryers, rollers and other rotating workpieces.The machine adopts ring belt drive or gear box universal joint transmission, and frequency conversion motor drive to ensure the balanced quality and precision of the workpiece.The machine has the characteristics of wide speed range, large driving power and high working efficiency. Model NumberPHQ-3000HPHW-3000H2460-10000HTransmissionBelt DriveUniversal JointUniversal JointWorkpiece weight range (kg)3000300010000Workpiece Ma

Contacter maintenant

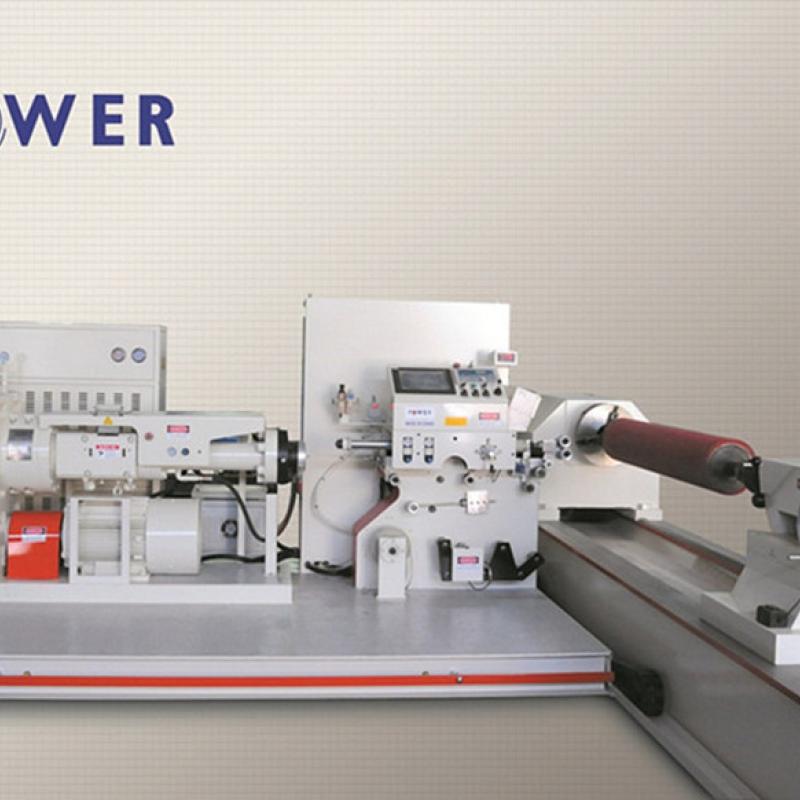

Factory Automatic Cylindrical Roll GrinderThe feature of PSM series Factory Automatic Cylindrical Roll Grinder1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max.

Contacter maintenant

1. Factory custom designed rubber curler groover has our personal advanced user-pleasant CNC running gadget.2. The modern CNC gadget can without difficulty perform extra than 35 shapes at the rubber curler surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, immediately groovings, etc. 3. Remote trouble fixing characteristic availabe.4. Having all of the capabilities of our PSM collection preferred grinding machineDue to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contacter maintenant

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contacter maintenant

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contacter maintenant

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contacter maintenant