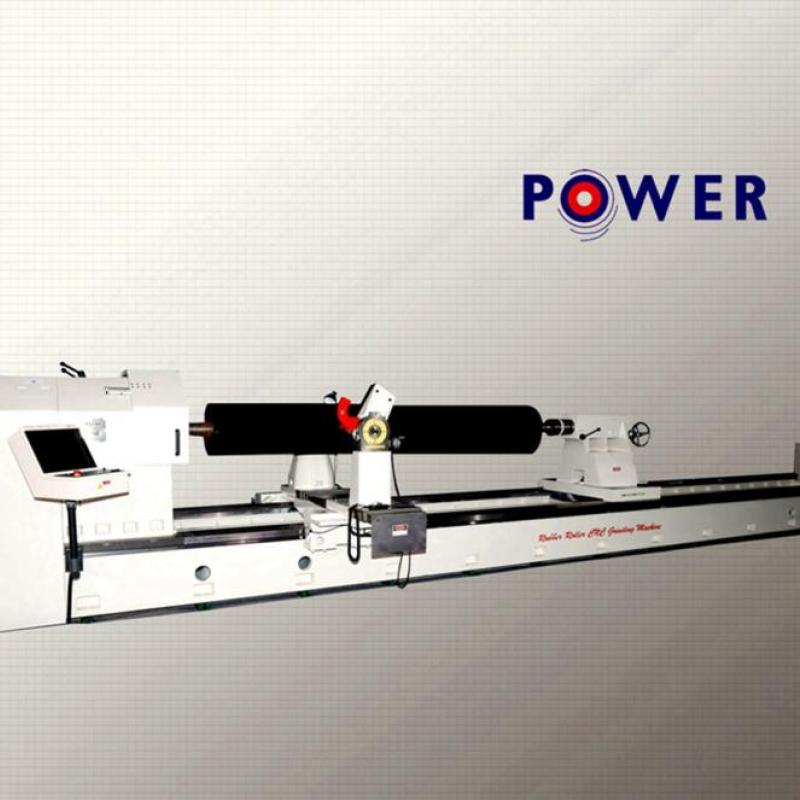

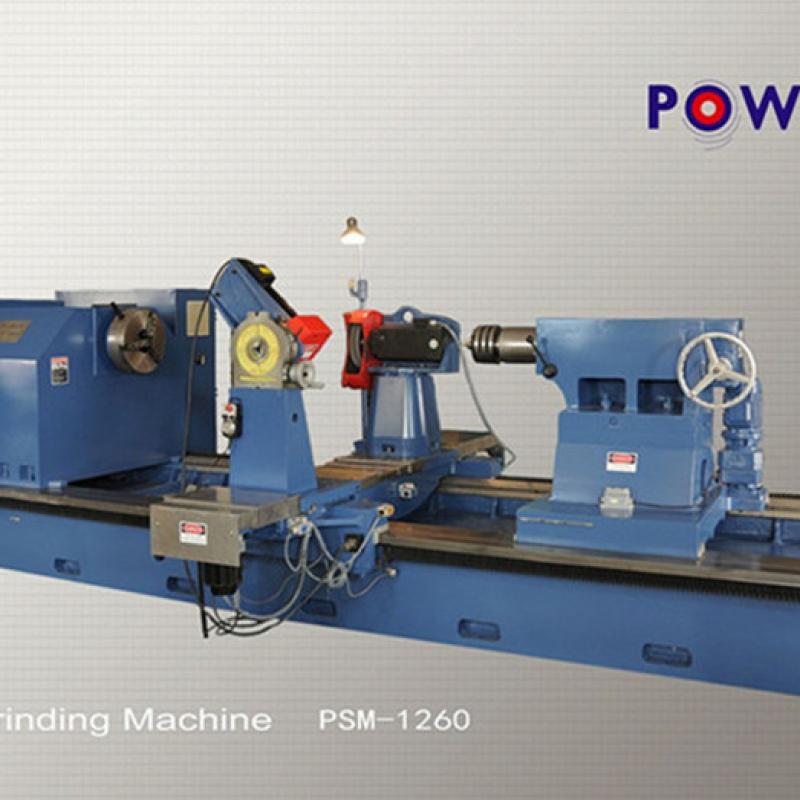

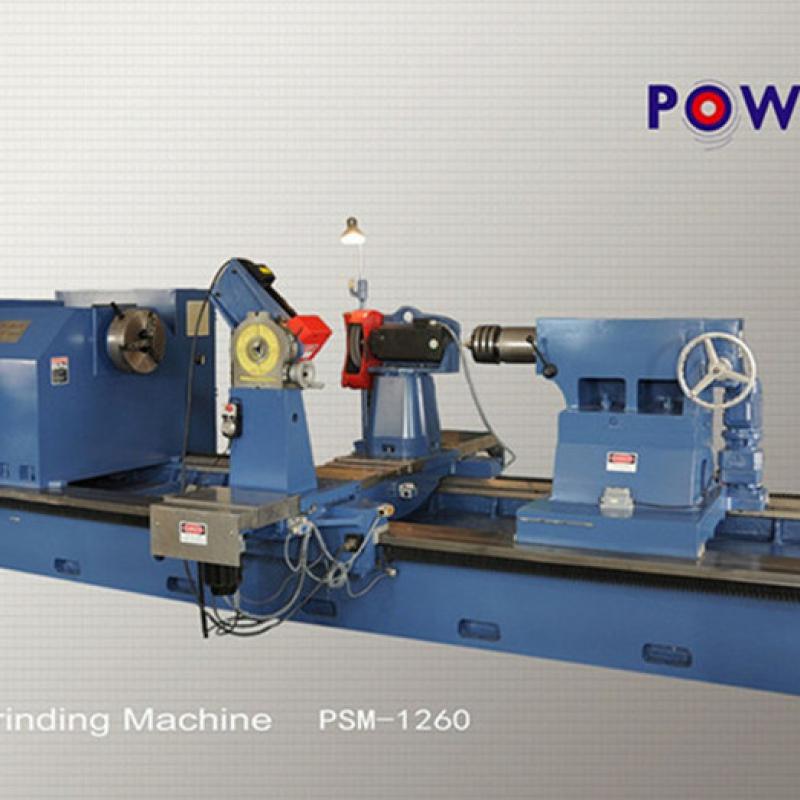

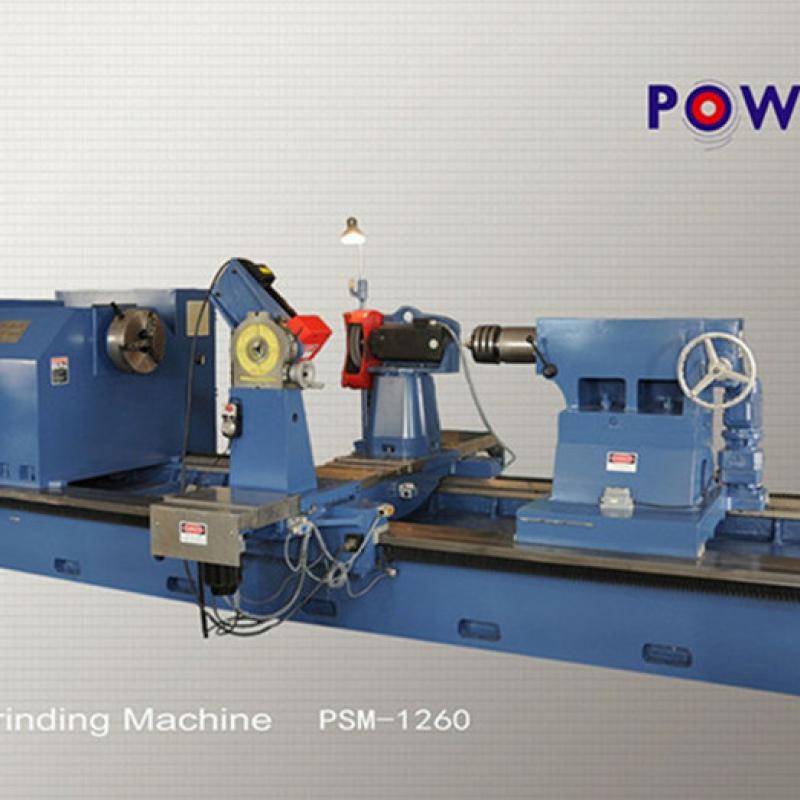

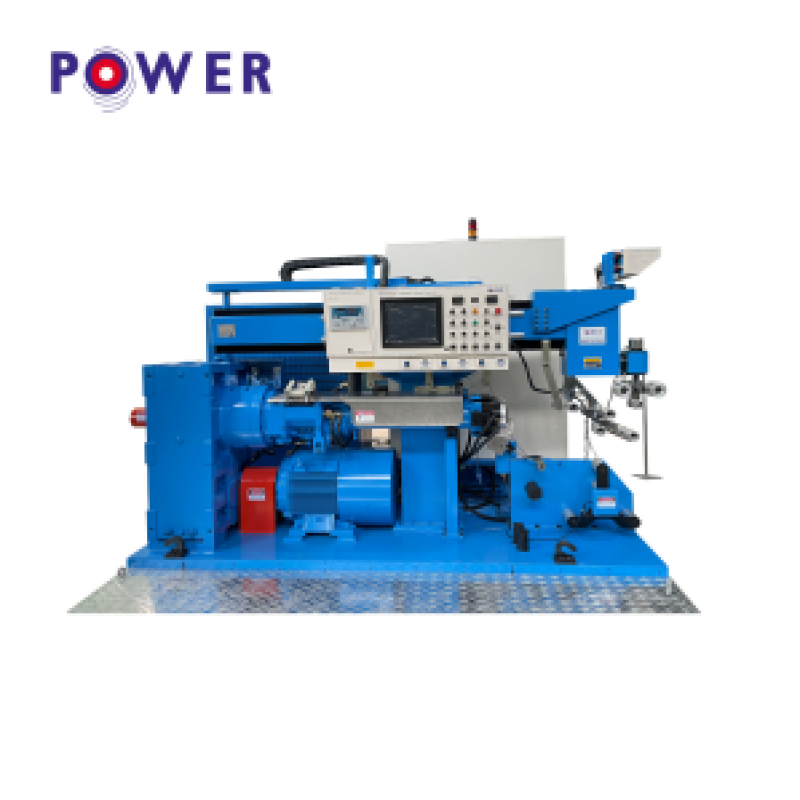

The feature of PSM series grinding machine for rubber roller processingPSM collection grinding system for rubber curler processing is eparticularly designed and synthetic to update the beyond curler processing approach via way of means of metal production equipment. Mounted grinding head at the engine lathe is the beyond approach to fabricate curler, which the pleasant of curler is hard to attain the requirement of the prevailing standard. The principal cause lies withinside the shape of lathe.

Contacter maintenant

The feature of PSM series grinding machine for rubber roller processing1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max. linear speed of grinding head is over 90m/s.

Contacter maintenant

PSM series grinding machine for rubber roller processing is particularly designed and artificial to replace the past roller processing approach with the useful resource of the usage of metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past approach to manufacture roller, which the high-excellent of roller is difficult to acquire the requirement of the present standard. The essential motive lies withinside the form of lathe.

Contacter maintenant

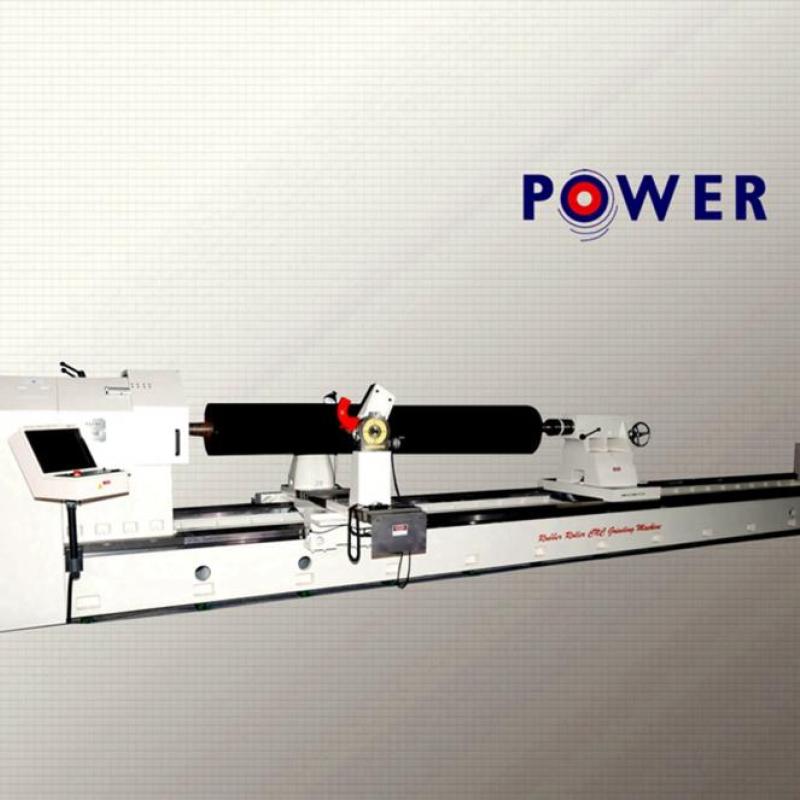

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding Machine1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b. motorized tailstock c. variable speed traverse and spindle drives d. front and rear independently operated carriage tables e. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3.

Contacter maintenant

PSM series grinding machine for rubber roller processing is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past method to manufacture roller, which the quality of roller is difficult to reach the requirement of the present standard. The main reason lies in the structure of lathe. After all, it is not the grinding machine; the moving spaces of the big and medium carriage table are larger than that of grinding machine.

Contacter maintenant

Rubber Roller Surface Grinding Machine for Paper The feature of PSM series rubber roller surface grinding machine for paper 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently operated.The feature of PSM series rubber roller surface grinding machine for paper1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contacter maintenant

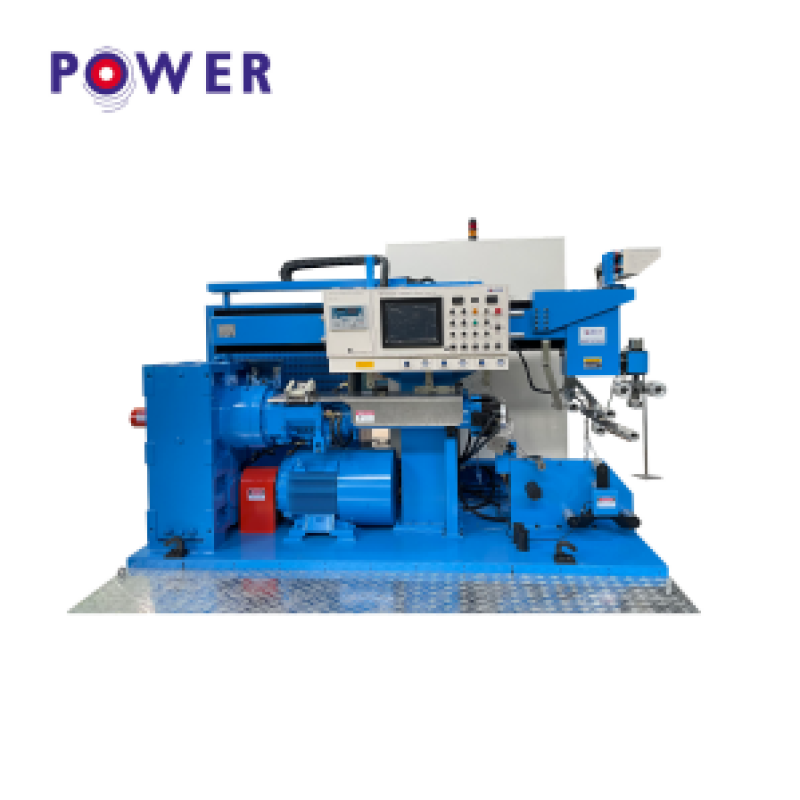

PCM Multi-Purpose Stripping Machine is eparticularly researched, evolved and designed for treating vintage Rubber Rollers. PCM Multi-cause Stripping Machine has the benefits that: Old rubber may be quick eliminated through a unique ring cutter, a curler middle could have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contacter maintenant

PSM-8040 General Rubber Roller Surface Grinding MachinePSM collection rubber curler grinding gadget is mainly designed and synthetic to replace the beyond roller processing approach by using way of steel production device. installation grinding head on the engine lathe is the past technique to fabricate curler, which the first-rate of curler is difficult to gain the requirement of the prevailing full-size. the primary purpose lies within the form of lathe.

Contacter maintenant

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding gadget is specifically designed and synthetic to replace the beyond curler processing method by way of metallic production equipment. set up grinding head at the engine lathe is the beyond approach to fabricate roller, which the high-quality of roller is hard to attain the requirement of the present widespread. the primary cause lies inside the shape of lathe. in the end, it isn't the grinding gadget; the shifting spaces of the large and medium carriage desk are large than that of grinding device.

Contacter maintenant

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacter maintenant

Product description1. the pcm-8040 model is suitable for renewing industrial rubber rollers.2. putting off antique rubber by way of special ring cutter.Three. replacing the conventional sand-blasting and solvent washing procedure by advanced belt-grinding process.4. flawlessly keeping the original dynamic balance of the roller middle.5. giving more dependable assure for the bonding of the rubber and metallic cores.6. saving fees and labors with this advanced manufacturing gadget.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacter maintenant

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contacter maintenant

Grinding Machine for Rubber Roller MakingThe feature of PSM series Grinding Machine for Rubber Roller MakingPSM series Factory Automatic Cylindrical Roll Grinder is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past method to manufacture roller, which the quality of roller is difficult to reach the requirement of the present standard. The main reason lies in the structure of lathe.

Contacter maintenant

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding system is in particular designed and artificial to update the past roller processing technique with the aid of using manner of steel manufacturing equipment. installation grinding head on the engine lathe is the past technique to manufacture curler, which the superb of curler is tough to gain the requirement of the existing widespread. the number one reason lies withinside the form of lathe.

Contacter maintenant

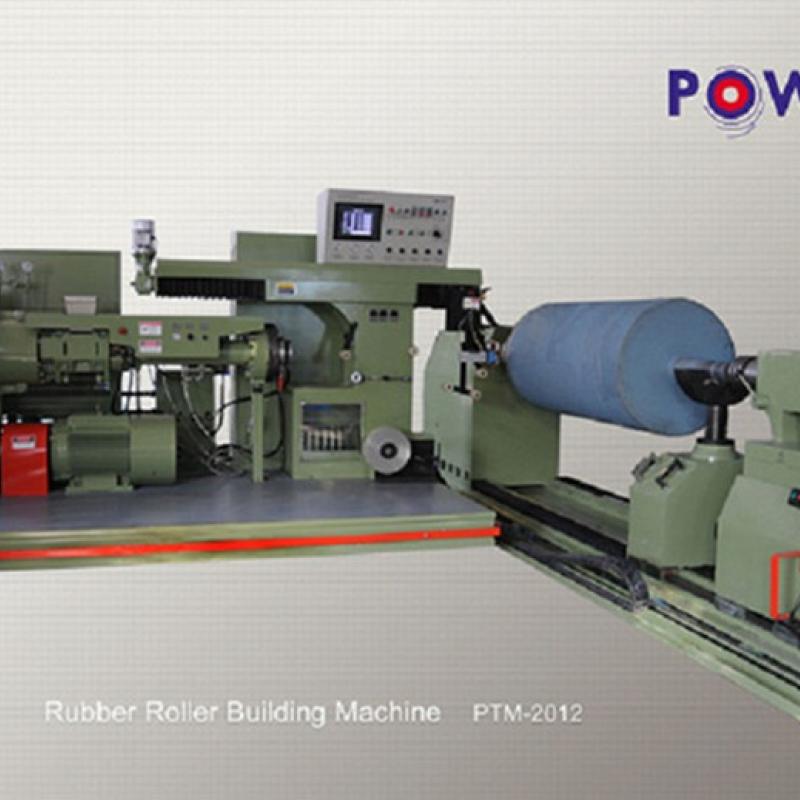

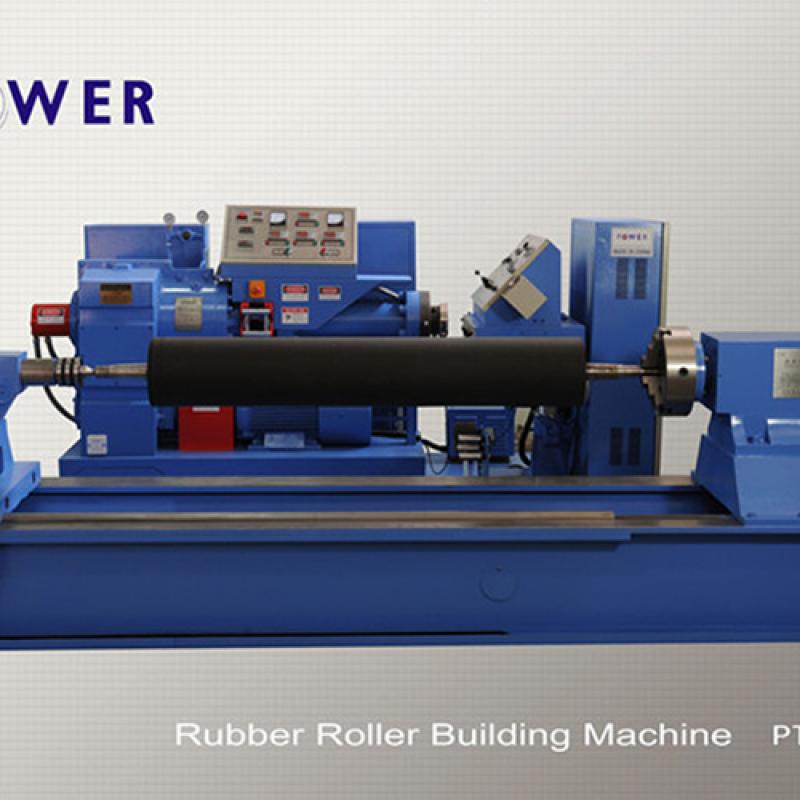

PTM-1510 Printing Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contacter maintenant

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber curler Covering Machine PTM-2012 version is appropriate for processing paper mill, mine transportation and heavy commercial rolls.2. Our rubber curler constructing system prepared with E350CS energy extruder and a whole commercial cooling system.3. The Rubber Roller Covering Machine is relevant to rubber compounding with all hardness variety 15-100A.4. The masking system is simple Installation with our expert technical support.5.

Contacter maintenant

PSM-8040 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding system is in particular designed and artificial to update the past curler processing technique with the aid of using the usage of manner of metallic manufacturing device. set up grinding head at the engine lathe is the beyond approach to manufacture roller, which the brilliant of roller is tough to benefit the requirement of the triumphing full-size. the number one reason lies withinside the shape of lathe.

Contacter maintenant

Factory Rubber Roller Grinding Machine For Textile The feature of PSM series factory rubber roller grinding machine for textile 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently.The feature of PSM series factory rubber roller grinding machine for textile1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contacter maintenant

Rubber Roller Surface Grinding Machine for Paper The feature of PSM series rubber roller surface grinding machine for paper 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently operated.The feature of PSM series rubber roller surface grinding machine for paper1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contacter maintenant

PSM collection rubber curler grinding system is eparticularly designed and synthetic to update the beyond curler processing technique via way of means of metal production equipment. Mounted grinding head at the engine lathe is the beyond technique to fabricate curler, which the best of curler is tough to attain the requirement of the prevailing standard. The fundamental cause lies withinside the shape of lathe. After all, it isn't always the grinding system; the transferring areas of the large and medium carriage desk are large than that of grinding system.

Contacter maintenant

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contacter maintenant

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1.

Contacter maintenant

Factory Rubber Roller Grinding Machine For Textile The characteristic of PSM collection manufacturing facility rubber curler grinding device for fabric 1 Standard system of PSM collection consists of a a complete flood recirculating coolant machine b motorized tailstock c variable pace traverse and spindle drives d the front and rear independently.The feature of PSM series factory rubber roller grinding machine for textile1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contacter maintenant

Product description1. The PCM-1660 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contacter maintenant